30 MINUTE CONCRETE REPAIR

30 MINUTE CONCRETE REPAIR

In 2007, Founder Richard Paul Giles, a Civil Infrastructure Expert, saw an opportunity to provide a high quality, low cost asphalt repair technology, which was selected in 2011 as best in class by Federal Highway Administration. The technology was also selected by Department of Defense for airfield runway repairs; Mr.Giles had Caterpillar and Bobcat as global distribution partners. Through his knowledge and expertise, Mr. Giles developed a simple 3-step concrete repair method that would reduce business or traffic disruptions and can be completed at a fraction of the cost. In 2012  contracted services with numerous NASCAR Sanctioned race venues, Deer Valley and several other ski resorts, cities, school districts, food chains and several other national brands.

contracted services with numerous NASCAR Sanctioned race venues, Deer Valley and several other ski resorts, cities, school districts, food chains and several other national brands.

contracted services with numerous NASCAR Sanctioned race venues, Deer Valley and several other ski resorts, cities, school districts, food chains and several other national brands.

contracted services with numerous NASCAR Sanctioned race venues, Deer Valley and several other ski resorts, cities, school districts, food chains and several other national brands.

Traditional Method

5,000 PSI

DAYS TO WEEKS

SUMMER MONTHS

COMPLETE CLOSURE

NONE

VS

STRENGTH

APPLICATION

REPAIR

WINDOW

TRAFFIC DISRUPTION

WARRANTY

30 Minute Repair

UP TO 20,000 PSI

30 MINUTES

YEAR ROUND

MINOR DISRUPTION

12 YEAR PRODUCT WARRANTY

30 Minute Repair

30 Minute Repair

Strength - Up to 20,000 PSI

Application - 30 Minutes

Repair Window - Year Round

Traffic Disruption - Minor

12 Year Product Warranty

VS

Traditional Method

Strength - 5,000 PSI

Application - Days to Weeks

Repair Window - Summer Months

Traffic Disruption - Complete Closure

Warranty - None

THE THREE STEP PROCESS

1. PREPARATION

First, the repair area is prepped by removing any deteriorated and damaged concrete. The area must be cleaned of any loose debris before application can begin. It’s important to give the concrete solution enough depth to anchor the surrounding structure. Once the loose concrete has been removed, the unfinished cracks can be ground down to allow for a more thorough bonding of the repair. Use leaf blower or broom to remove all debris, clean and let dry (use simple green if necessary).

2. MIXING

The 30 Minute Repair product is a patented polymer Hybrid Composite concrete repair formula. After years of extensive research is pleased to provide this unrivaled product. It comes packaged in individual pre-measured bags to allow for an easier mixing process. Simply add all the ingredients into an induction mixer and in 3 minutes the repair solution will be ready to apply. The 30 Minute Repair is up to 4x stronger than concrete and is ready for returned use in minutes not days.

3. APPLICATION

The third and final step is to apply the mixed material to the repair area. This is where the material is spread out, leveled and finished with a hand trowel for the appropriate thickness and slope. Then the material is dusted with a powder to best match the color of the surrounding area. After the simple 3-step concrete repair process is complete, you only need to allow approximately 60 minutes for the material to cure*. At this time, you will be able to walk or drive on the repaired area. *Final cure time may vary depending on outside temperatures.

THE  THREE STEP PROCESS

THREE STEP PROCESS

1. PREPARATION

First, the repair area is prepped by removing any deteriorated and damaged concrete. The area must be cleaned of any loose debris before application can begin. It’s important to give the  concrete solution enough depth to anchor the surrounding structure. Once the loose concrete has been removed, the unfinished cracks can be ground down to allow for a more thorough bonding of the repair. Use air blower or broom to remove all debris, clean and let dry (use simple green if necessary).

concrete solution enough depth to anchor the surrounding structure. Once the loose concrete has been removed, the unfinished cracks can be ground down to allow for a more thorough bonding of the repair. Use air blower or broom to remove all debris, clean and let dry (use simple green if necessary).

concrete solution enough depth to anchor the surrounding structure. Once the loose concrete has been removed, the unfinished cracks can be ground down to allow for a more thorough bonding of the repair. Use air blower or broom to remove all debris, clean and let dry (use simple green if necessary).

concrete solution enough depth to anchor the surrounding structure. Once the loose concrete has been removed, the unfinished cracks can be ground down to allow for a more thorough bonding of the repair. Use air blower or broom to remove all debris, clean and let dry (use simple green if necessary).2. MIXING

The  30 Minute Repair product is a patented polymer Hybrid Composite concrete repair formula. After years of extensive research

30 Minute Repair product is a patented polymer Hybrid Composite concrete repair formula. After years of extensive research  is pleased to provide this unrivaled product. It comes packaged in individual pre-measured bags to allow for an easier mixing process. Simply add all the ingredients into an

is pleased to provide this unrivaled product. It comes packaged in individual pre-measured bags to allow for an easier mixing process. Simply add all the ingredients into an  induction mixer and in 3 minutes the repair solution will be ready to apply. The

induction mixer and in 3 minutes the repair solution will be ready to apply. The  30 Minute Repair is 4x stronger than concrete and is ready for returned use in minutes not days.

30 Minute Repair is 4x stronger than concrete and is ready for returned use in minutes not days.

30 Minute Repair product is a patented polymer Hybrid Composite concrete repair formula. After years of extensive research

30 Minute Repair product is a patented polymer Hybrid Composite concrete repair formula. After years of extensive research  is pleased to provide this unrivaled product. It comes packaged in individual pre-measured bags to allow for an easier mixing process. Simply add all the ingredients into an

is pleased to provide this unrivaled product. It comes packaged in individual pre-measured bags to allow for an easier mixing process. Simply add all the ingredients into an  induction mixer and in 3 minutes the repair solution will be ready to apply. The

induction mixer and in 3 minutes the repair solution will be ready to apply. The  30 Minute Repair is 4x stronger than concrete and is ready for returned use in minutes not days.

30 Minute Repair is 4x stronger than concrete and is ready for returned use in minutes not days.3. APPLICATION

The third and final step is to apply the mixed material to the repair area. This is where the material is spread out, leveled and finished with a hand trowel for the appropriate thickness and slope. Then the material is dusted with a powder to best match the color of the surrounding area. After the  simple 3-step concrete repair process is complete, you only need to allow approximately 60 minutes for the material to cure. At this time, you will be able to walk or drive on the

simple 3-step concrete repair process is complete, you only need to allow approximately 60 minutes for the material to cure. At this time, you will be able to walk or drive on the  repaired area.

repaired area.

simple 3-step concrete repair process is complete, you only need to allow approximately 60 minutes for the material to cure. At this time, you will be able to walk or drive on the

simple 3-step concrete repair process is complete, you only need to allow approximately 60 minutes for the material to cure. At this time, you will be able to walk or drive on the  repaired area.

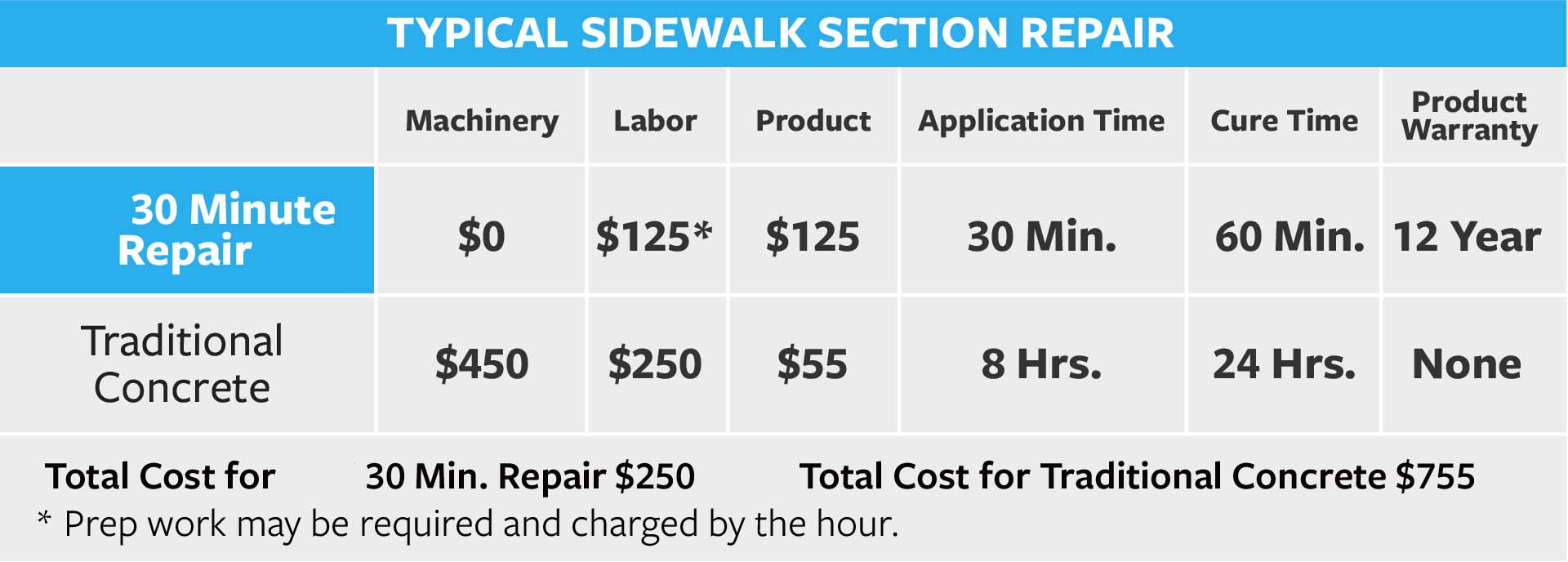

repaired area.COST COMPARISON

The cost savings of the 30 minute repair are multi-faceted. Not only does the repair last longer than other methods, it doesn't require the intensive remove and replace process that traditional concrete repair requires. More copy distinguishing the finer, though fundamental differences between the 30 Minute Repair and Traditional Concrete Repair.

Typical Sidewalk Section Repair

*Prep work may be required and charged by the hour.

Total cost for Traditional Concrete Repair - $755

Total cost for 30 Minute Repair - $250

START REPAIRING OUR NATIONS INFRASTRUCTURE

Become an Area Developer with an exclusive territory of franchisees to help manage and grow or become a franchisee to have your own  concrete repair business!

concrete repair business!  will help support you through either process by providing training, marketing materials, sales tools and the necessary equipment. Become your own boss and take advantage of this $84 Billion concrete repair market and claim your exclusive territory now!

will help support you through either process by providing training, marketing materials, sales tools and the necessary equipment. Become your own boss and take advantage of this $84 Billion concrete repair market and claim your exclusive territory now!

concrete repair business!

concrete repair business!  will help support you through either process by providing training, marketing materials, sales tools and the necessary equipment. Become your own boss and take advantage of this $84 Billion concrete repair market and claim your exclusive territory now!

will help support you through either process by providing training, marketing materials, sales tools and the necessary equipment. Become your own boss and take advantage of this $84 Billion concrete repair market and claim your exclusive territory now!AREA DEVELOPER

FRANCHISE